In the heartland of America, Kansas-based automotive suppliers face a unique set of challenges in their pursuit of precision and efficiency. One technology that has emerged as a crucial solution to these challenges is Sinker EDM, short for Electrical Discharge Machining. Sinker EDM is a specialized machining process that plays a pivotal role in addressing specific obstacles encountered by automotive suppliers. In this article, we will delve into the challenges faced by Kansas-based automotive suppliers and how Sinker EDM proves to be a game-changer in overcoming these hurdles.

The Landscape of Challenges

1. Tight Tolerances and Complex Geometries

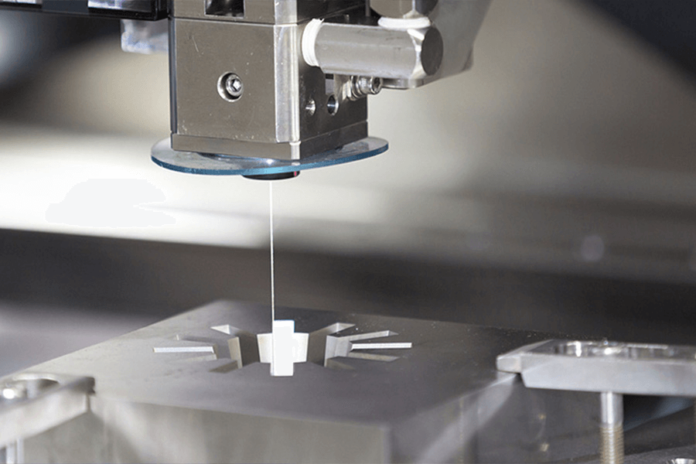

In the competitive automotive industry, manufacturers in Kansas are often tasked with producing components with tight tolerances and intricate geometries. Achieving such precision can be a daunting task with conventional machining methods. This is where Sinker EDM steps in, offering a solution that allows for the production of intricate components with unparalleled accuracy. By utilizing electrical discharges to erode materials, Sinker EDM ensures that even the most complex shapes can be replicated with utmost precision.

2. Hardened Materials and Tool Wear

Automotive components are frequently made from hardened materials to enhance durability and performance. Traditional machining methods struggle when confronted with these hardened materials, leading to increased tool wear and decreased efficiency. Sinker EDM, however, excels in machining hardened materials, making it the ideal choice for automotive suppliers in Kansas. The process significantly reduces tool wear, ensuring longer tool life and minimizing the need for frequent replacements.

3. Minimizing Residual Stresses and Micro-Cracks

Heat-affected zones, residual stresses, and micro-cracks are common concerns in the machining of automotive components. These issues can compromise the structural integrity and longevity of the final product. Sinker EDM’s non-contact machining process mitigates these concerns by minimizing heat-affected zones, resulting in components with improved mechanical properties. Kansas-based automotive suppliers can thus rely on Sinker EDM to produce high-quality components with enhanced structural integrity.

The Sinker EDM Advantage

Sinker EDM, with its unique capabilities, provides a transformative solution to the challenges faced by Kansas-based automotive suppliers. Its ability to achieve precision in tight tolerances, work with hardened materials, and minimize the impact of residual stresses positions it as a key player in the pursuit of excellence in manufacturing. By incorporating Sinker EDM into their operations, automotive suppliers can enhance efficiency, reduce costs associated with tool wear, and deliver superior products to their clients.

Why Choose Sinker EDM for Your Kansas-based Automotive Supply Needs?

1. Precision Beyond Limits

Sinker EDM’s precision is unparalleled, allowing Kansas-based automotive suppliers to meet and exceed industry standards. The technology’s ability to replicate intricate geometries with minimal deviation ensures that components are manufactured with the utmost accuracy, meeting the stringent requirements of the automotive sector.

2. Extended Tool Life

One of the significant challenges faced by manufacturers is the frequent replacement of tools due to wear. Sinker EDM addresses this challenge by significantly extending tool life when compared to conventional machining methods. This results in cost savings for automotive suppliers in Kansas, making their operations more economical and sustainable.

3. Versatility in Material Machining

The ability to work with hardened materials sets Sinker EDM apart from traditional machining methods. Kansas-based automotive suppliers can confidently machine a wide range of materials, including hardened steel and alloys, expanding the possibilities for component design and ensuring the production of durable, high-performance automotive parts.

4. Reduced Residual Stresses

Residual stresses and micro-cracks can compromise the structural integrity of automotive components. Sinker EDM’s non-contact machining process minimizes heat-affected zones, effectively reducing the impact of residual stresses. This results in components with enhanced mechanical properties, contributing to the longevity and reliability of the final product.